Like any other product evaluation, pharmaceutical products are also evaluated using various analytical tests. Following the product development stage, these tests become quality control or assurance tests and are required to be conducted to establish the quality of the products for sale. Commonly, pharmacopeial, such as USP, standards are followed for this purpose.

For solid oral pharmaceutical products such as tablets and capsules, these tests include (1) Identification – to establish or confirm the expected identity of the drug within a product; (2) Assay or Potency – to establish the presence of the expected amount of drug in the product; (3) Uniformity of Content – to establish unit to unit (tablet/capsule) variation in the drug amount (4) Drug release/dissolution test – to establish that the drug would be released from the product in an expected and reproducible manner.

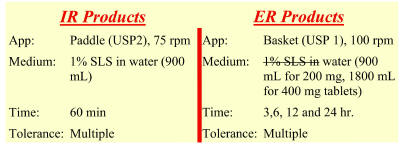

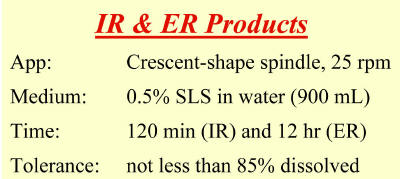

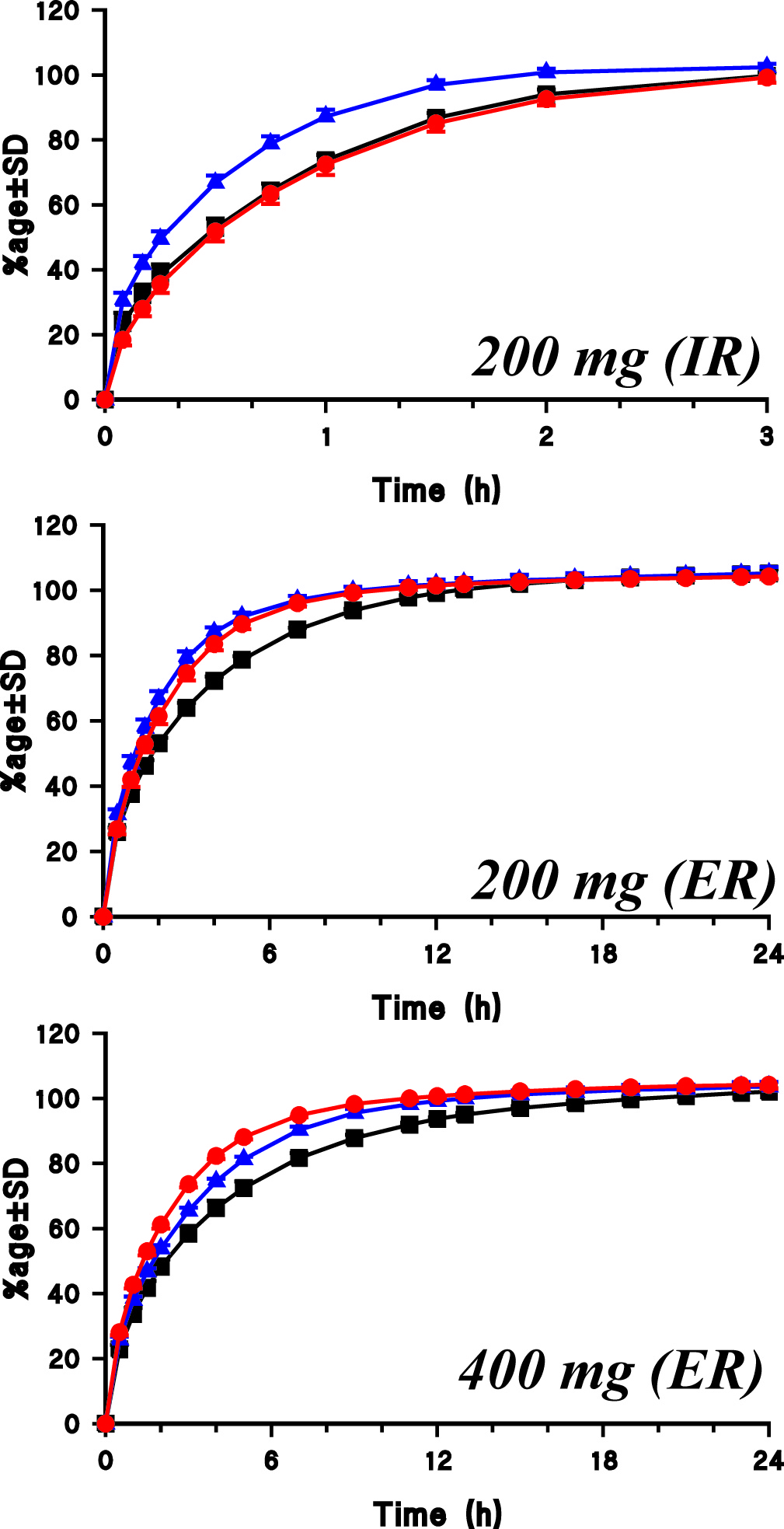

These tests are usually conducted separately. One common aspect of these tests is that these all usually require an extraction step followed by quantitation using chromatographic or spectrophotometric methods. Drug dissolution testing by itself is an extraction-based test in which a drug from the product is extracted in an aqueous-based solvent (e.g. water or buffer having pH 5-7) maintained at 37 ºC. The extraction using an aqueous-based solvent mimics the physiological environment of the human GI tract, where the drug is expected to be released for absorption. Drug dissolution testers, therefore, become a drug extracting apparatus or extractor. However, these apparatuses are not considered or have not been used as extractors because the apparatus’s stirring and mixing process is poor, thus providing poor extractions. Considering the poor stirring and mixing aspect of these apparatuses, in particular Paddle and Basket, these apparatuses do not generally provide an accurate reflection of the drug release characteristics of products, as has been reported frequently in the recent literature. To address this artifact of poor stirring and mixing within a dissolution tester, recently, a modified stirrer, known as crescent-shaped spindle, has been suggested for the dissolution apparatuses. It makes an apparatus an efficient extractor and thus provides improved drug dissolution characteristics.

With this modification, the apparatus may also be utilized as any other extractor and may be used for other above-mentioned tests. Thus, all the above-mentioned tests can be conducted using dissolution tester/extractor with the modified spindle or stirrer.

By reversing the logic, one could say that this modified dissolution tester may be used to conduct assays, content uniformity, and identification tests. However, rather than using a harsh stirring condition, as commonly used for such tests, one would use gentler conditions such as 25 rpm, thus the extraction step will become a dissolution test as well. Therefore, in a single step one would be able to evaluate all these attributes.

There are a number of advantages of using this approach. (1) Obviously, it will provide significant economic savings as one vs. four test would be needed. In addition, testing or product evaluation will be completed extremely fast, thus, saving time. (2) The testing will be more physiologically relevant as the test conditions (medium or stirring) mimic the GI tract environment. At present, tests are usually conducted without concern of the physiological aspect. These tests are usually conducted using organic solvents, high pH aqueous solvents, along with high impact processes such as crushing and extracting and at high rpms in blenders or using a mortal and pastel. (3) With the new spindle, the recommended experimental conditions are water (with or without a solubilizer) and 25 rpm, thus, nearer to physiological relevancy.

A dissolution tester, thus, with crescent-shaped spindle provides not only more appropriate drug dissolution evaluation but also simultaneously provides answers for other quality tests. Hence, the term One Step (Product Evaluation) Approach is coined, reflecting improved testing along with savings of time and money. For further description about using a dissolution tester, please see the publication for other quality parameters. The Open Drug Delivery Journal, 2008, 2, 33-37. (Link)